Introduction

JC624 compact pressure transmitter has features of anti-corrosion, anti-wear, shock resistance and vibration resistance. Its anti-overload capacity is over 10 times of the range, completely solved poor overload in small range of other sensors. In addition to general ranges of normal sensors, its most outstanding characteristic is the positive and negative gauge pressure function. JC624 compact pressure transmitter is a civil and industrial product with large consumption and low costs, for which a new standard of cost performance has been established. This series of products is widely used for pneumatic and hydraulic detection even in very harsh medium environment such as sewage, vapor, slight corrosive liquid and gas.

Features

* Excellent anti-corrosive and anti-wear performance;

* Suitable for pollution and corrosive environment;

* Various electrical connectors available;

* Rapid response, no hysteresis;

* Anti-Icing;

* Accurate, stable and reliable;

* 0.5..4.5V and 4.20MA analog output, I2C and SPI digital output;

* Refrigeration equipment — Freon or ammonia

Application

* Pressure measurement of gas, vapor or liquid in various areas

* Integrated in a variety of user-defined solutions

* Pump and compressor

* Hydraulic and pneumatic system

* Energy and water treatment system

* Automatic detection system

* Agricultural equipment

* Refrigeration equipment — Freon or ammonia

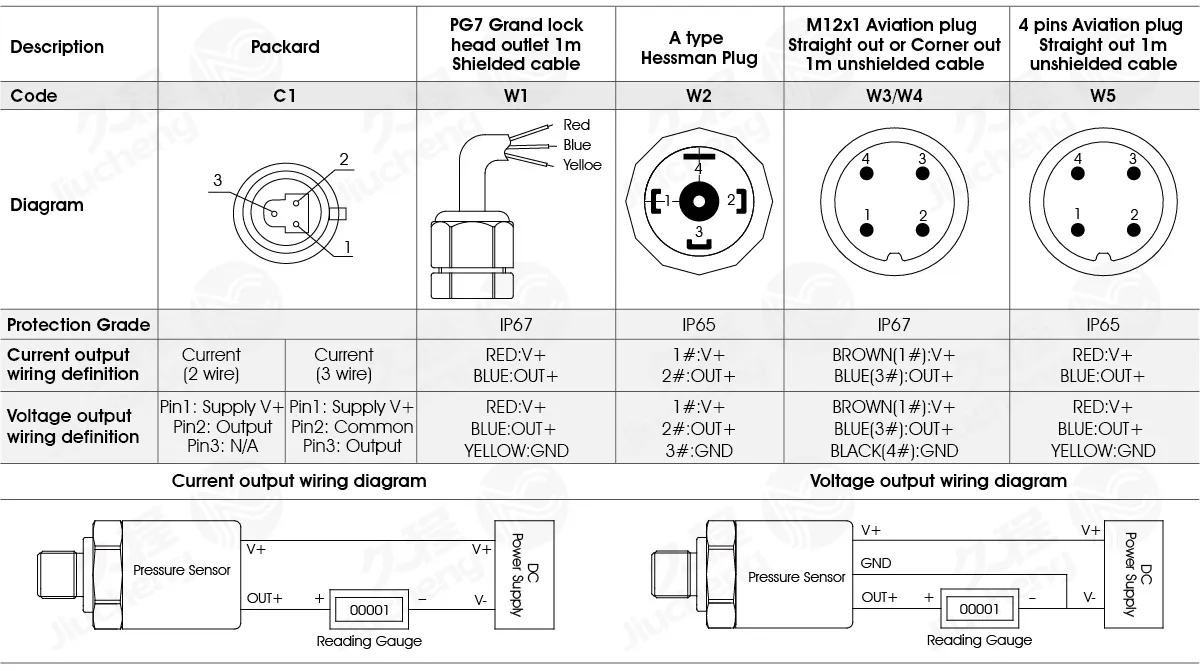

Electrical Connections

Technical Parameters

| Sensor Range | 0-40KPa, 1MPa,2MPa,5MPa,10MPa, 15MPa…20Pa…50MPa… 100 MPa customized | |

| Input | Pressure type | Gauge pressure, sealing pressure, absolute pressure |

| Overload Capacity | 2 times of full–scale pressure. Maximum 110MPA | |

| Measuring media | The gas or liquid compatible with 316 stainless steel or ceramic | |

| Signal output | Analog | mV DC,0.5…4.5V, 4…20mA, 0…10V, 1…5V,0…5V |

| Digital | I2C, SPI | |

| Accuracy | 0.50% | Linearity, hysteresis, repetitiveness; <0.5% sensor full range |

| 1% | Linearity, hysteresis, repetitiveness; <1% sensor full range | |

| Long-term stability | ±0.25%FS/year | |

| Operating temperature | -20~+85℃ | |

| Compensation temperature | -10~+50℃ | |

| Thermal hysteresis | ±0.1%FS(typical) | |

| Power Supply | Supply voltage | 5VDC, 12~36 VDC (24V DC typical) |

| Supplier voltage effect |

5V supply voltage effect: min 3V/max5.5V For 0. 5….4.5V output sensor, voltage has no effect for linearity and temperature compensation, voltage is proportional to LRV and FRV For I2C and SPl digital output sensor, voltage has no effect for linearity, LRV, URV and compensation temperature. 24V supply power effect: min 9V/max30v For 4….20MA current output sensor, voltage has no effect for linearity, LRV, URV and compensation temperature. |

|

| Electrical connection | PG7cable connection | Connector DIN43650 |

| Enclosure protection class | IP67(cable type) | IP65(socket type) |

| Response time(10%~90%) | ≤3ms | |

| Load resistance | ≤(U-12)/0.02 Ω | |

| Insulation resistance | 100MΩ,500VDC | |

| Vibration error | ≤±0.01%FS(Axes X,Y,Z,200Hz/g) | |

| Weight | Approx. 250g | |

Ordering Information

| JC624 | Compact Pressure Transmitter | ||||||

| Code | Pressure type | ||||||

| G | Gauge pressure (G may not be indicated) | ||||||

| S | Sealing pressure | ||||||

| A | Absolute pressure | ||||||

| Range | Measuring range | ||||||

| 0~ X KPa or MPa | |||||||

| Code | Overall accuracy (linearity + repeatability + hysteresis) | ||||||

| 1 | ±0.5%FS | ||||||

| 0 | 1%FS | ||||||

| Code | Signal output | ||||||

| A1 | 4~20mA | ||||||

| V1 | 1~5V DC | ||||||

| V2 | 0~5V DC | ||||||

| V3 | 0.5~4.5V DC | ||||||

| V4 | I²C | ||||||

| V5 | SPI | ||||||

| X | Customized | ||||||

| Code | Electrical connector | ||||||

| C1 | Packard | ||||||

| C2 | M12x4P | ||||||

| C3 | Cable Outlet (the cable length needs to be advised while ordering) | ||||||

| C4 | Mini DIN43650 | ||||||

| C5 | GX12-3 | ||||||

| CX | Customized | ||||||

| Code | Process connector | ||||||

| F1 | M20X1.5 male thread | ||||||

| F2 | G1/4 male thread | ||||||

| F3 | 1/4 NPT male thread | ||||||

| F0 | Customize | ||||||

| JC624(0~2MPa)G—1 —A1 —C1—F2 Compact Pressure Transmitter | |||||||

Tips for Type Selection

1. The medium to be measured shall be compatible with the material contacting with the product.

2. As an additional function code for type selection, the code “E” for intrinsically safe explosion-proof type Ex iaIICT6 denotes that power source must be supplied via safety barrier

3. For other special requirements, please discuss with us and clearly indicate them in the order.