Introduction

JC670 hygienic flat-diaphragm pressure transmitter adopts imported high-accuracy and high-stability pressure sensor module to covert the absolute pressure or the gauge pressure of the measured medium into 4 ~ 20mA, 1 ~ 5V / 0 ~ 5V standard electrical signal through high-reliability amplification circuit and precise temperature compensation. High-quality sensor and encapsulation technology of full seal welding as well as improved assembling process have ensured excellent quality and best performance of this series of product.

Features

* High stability and high sensitivity

* Lightning and RFI immunity

* Fully made of stainless steel

* Clean flat type isolating diaphragm

* Diversified signal output form and adjustable zero

* Point and full scale

* polarity protection and transient over-current and over-voltage protection

Application

* Hygienic pressure pipelines

* Food and beverage processing

* Medical and pharmaceutical

* Sewage treatment

* Viscous medium pressure measurement

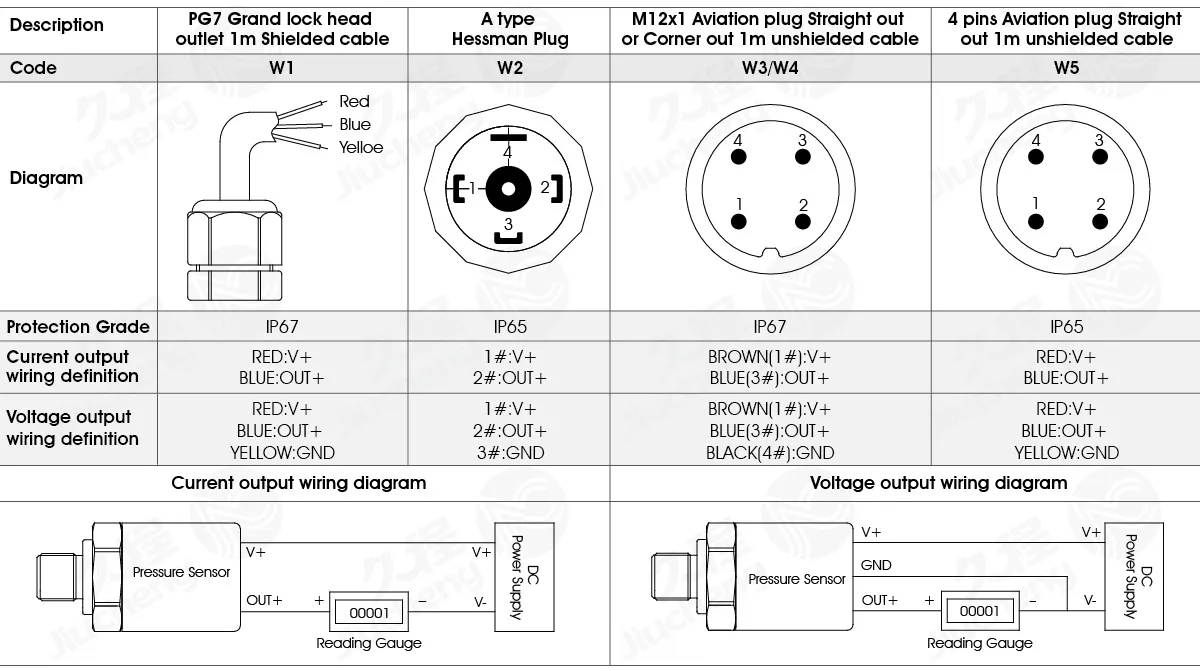

Electrical Connections

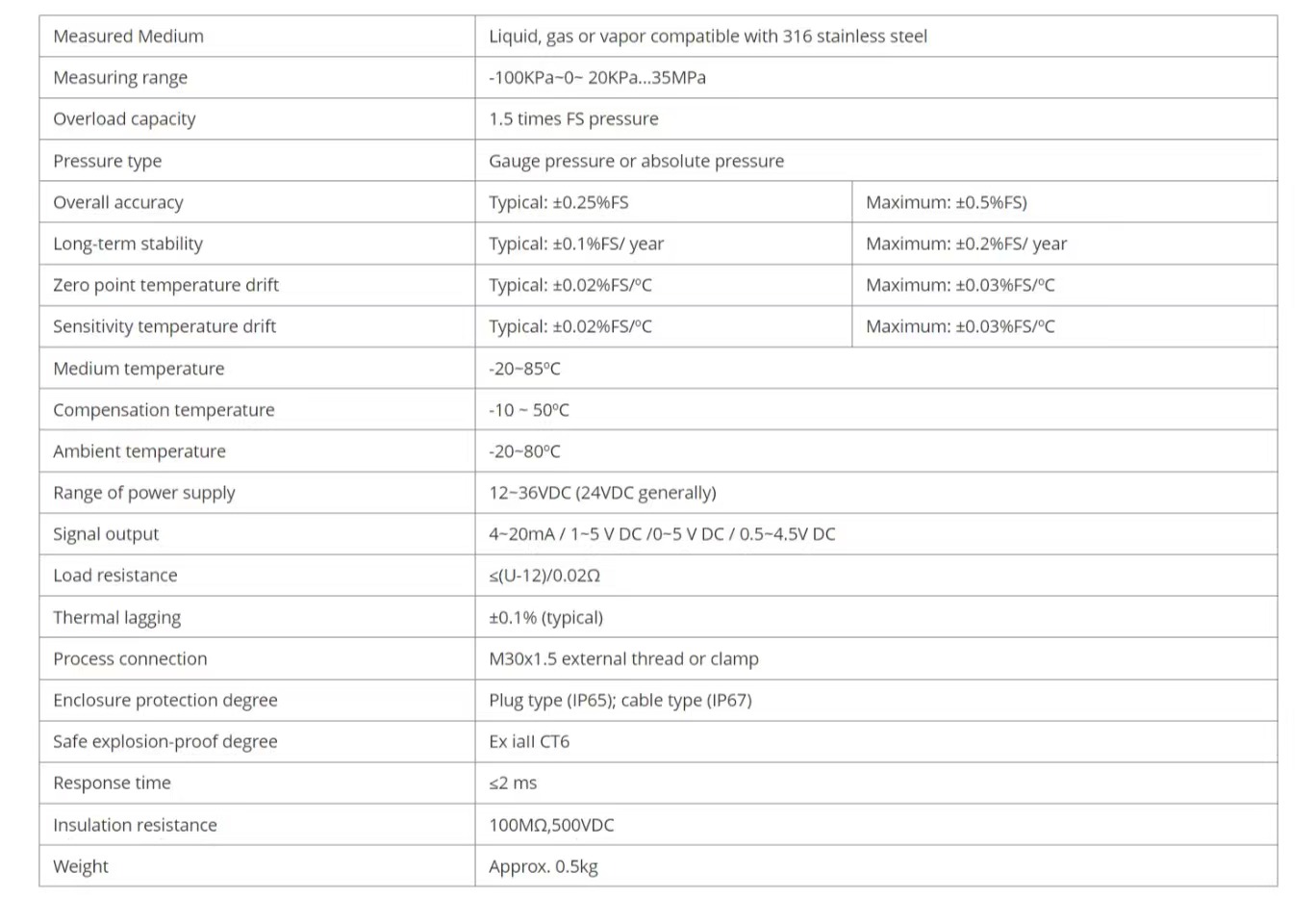

Technical Parameters

Ordering Information

| JC670 | Hygienic Flat-diaphragm Pressure Transmitter | |||||

| Pressure type | Gauge pressure ( G, may not be indicated); absolute pressure (A) | |||||

| Range | Measuring Range | |||||

| ( 0~ X KPa or MPa) | ||||||

| Code | Overall accuracy (linearity + repeatability + lagging) | |||||

| 1 | ±0.5%FS | |||||

| 2 | ±0.25%FS | |||||

| 3 | ±0.1%FS | |||||

| Code | Signal Output | |||||

| A1 | 4~20mA | |||||

| V1 | 1~5V DC | |||||

| V2 | 0~5V DC | |||||

| V3 | 0.5~4.5V DC | |||||

| Code | Additional functions | |||||

| F1 | M30x1.5 external thread | |||||

| F2 | Clamp type | |||||

| F0 | Special | |||||

| W1 | Cable type (IP67, 2m) | |||||

| W2 | Socket type (IP65, DIN43650) | |||||

| E | ntrinsically safe explosion-proof type Ex iaIICT6 | |||||

| JC670 (0~100KPa)-1 -A1 -F1-W1 Hygienic Flat-diaphragm Pressure Transmitter | ||||||

Tips for Type Selection

1. The measured medium shall be compatible with the material contacting with the product.

2. The code E, an additional function code for selection, namely, intrinsically safe explosion-proof Ex iaIICT6, must be power supplied via safety barrier.

3. Please contact us for other special requirements and clearly indicate them in the order.

4. During the field installation of flat diaphragm, the correct sealing method shall be adopted to prevent the installation stress influencing product stability.